QLCut Sheet metal laser cutting control system

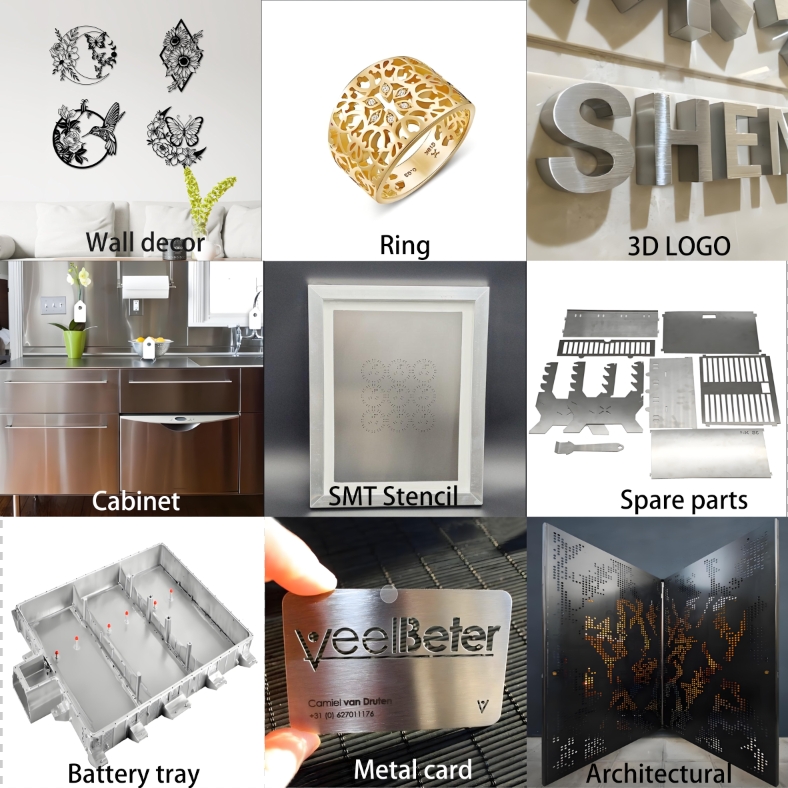

Application

![]()

Stainless steel, carbon steel, cold-rolled sheets, and other metal laser cutting and drilling processing applications

System Overview

The SuperFar Intelligent QLCut new-generation intelligent sheet metal cutting system supports 4-axis pulse/direction and EtherCAT bus control, and integrates an analog fully-closed-loop height control axis. This enables a single card to control all machine motion and height adjustment, delivering a high-precision, high-efficiency laser sheet metal cutting solution.

System Architecture

The QLCut sheet metal cutting software works with the QLC-520 four-axis motion controller, which features a built-in height regulator and SuperFar self-developed sheet metal cutting head. This streamlined setup simplifies wiring and allows a single card to manage all machine motion functions.

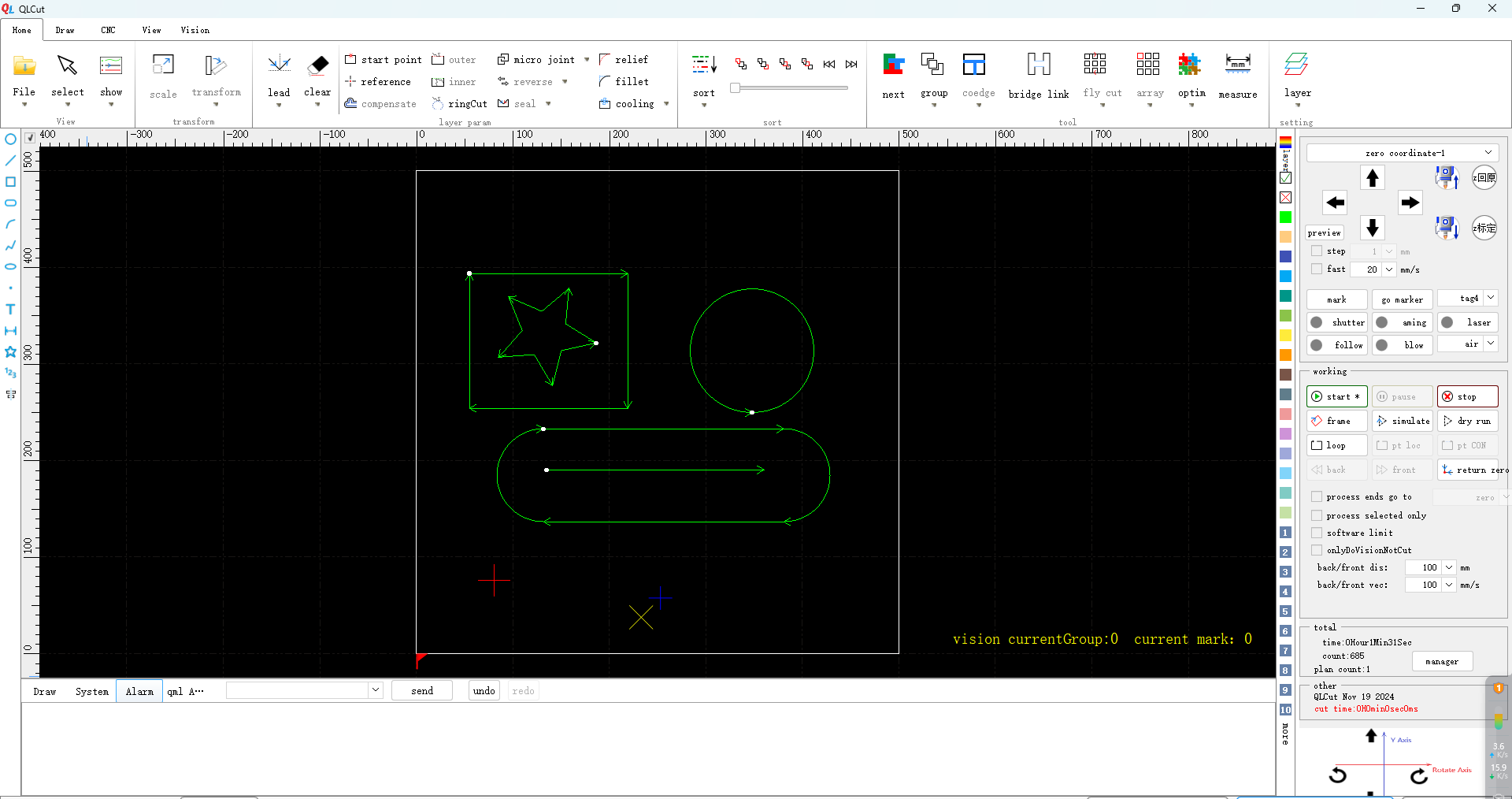

Software

QLCut Sheet metal cutting software

Technical Module | Innovation Design Highlights |

Integrated Design | Built-in height regulator enables a single card to control all machine motions. |

Fly Cutting | Path-optimized algorithm eliminates deceleration segments, increasing speed by 30% |

Smart nesting | Supports automatic nesting with ultra-high material utilization, reducing material costs. |

Algorithm Optimization | Jerk-controlled acceleration/deceleration algorithm ensures smooth motion, high efficiency, and precision during cutting. |

Common-Edge Cutting | Supports automatic common-edge cutting to improve overall cutting efficiency. |

Micro-Joints | Enables mark-free micro-joints for convenient batch unloading. |

Multi-Stage Piercing | Supports multi-stage piercing to enhance processing efficiency for thick plates. |

Visual Positioning | Sub-pixel accuracy (±3μm) combined with thermal deformation compensation. |

Strong Anti-Interference | Supports individual encoder filtering for each axis, ensuring reliability in harsh environments. |

High Extensibility | Software supports custom I/O, PLC logic, and script automation for rapid implementation of automated production. |

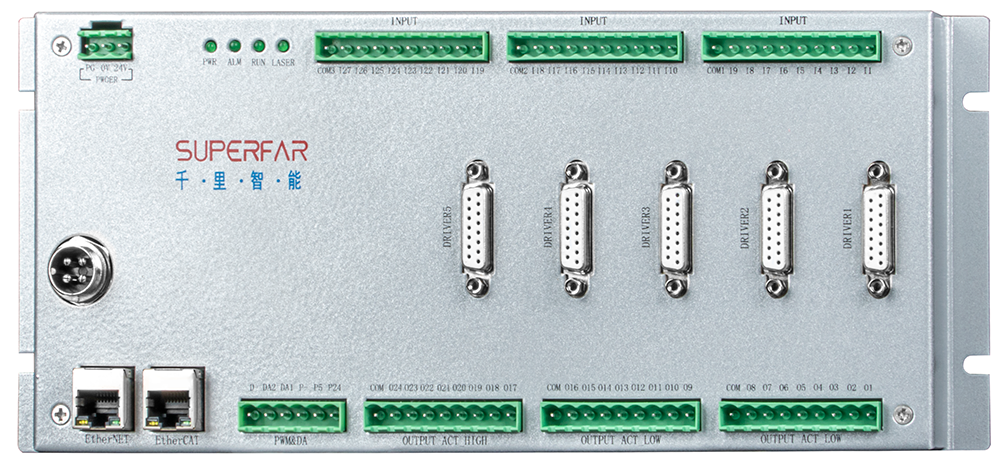

Hardware

4 Axis motion contrl card QLC-520(CUT)

Category | Description |

Control Features | - Supports 4-axis pulse/direction and EtherCAT bus control - Excellent anti-interference capability with independent encoder filtering for each axis - Built-in height regulator control - a single card handles all machine motion functions - 1ms control cycle with filtered S-curve acceleration/deceleration, look-ahead, and corner optimization algorithms |

Computing Performance | - QLC-520cut platform equipped with high-performance digital processing unit. - Ultra-short servo cycle suitable for high-speed, high-precision scenarios |

Communication Capabilities | - EtherNET 1000M Ethernet communication - Independent operating system |

EtherCAT Interface | - Simplified wiring, exceptional scalability, and robust anti-interference performance |

Data Storage | - Large-capacity memory architecture supporting high-speed data throughput applications - Four-channel encoder input + four-axis pulse output -Two-channel ±10V DAC analog output. -24-output/27-input IO, support customized option |

Application | Stainless steel, carbon steel, cold-rolled sheets, galvanized sheets, copper materials, aluminum substrates, and other metal laser processing applications. |

About Us

Shenzhen SuperFar Intelligent Control Technology Co., Ltd

Step by step, the miles are gained; Floor by floor, the view's obtained.

SuperFar located in Shenzhen, has a core competitive technical team dedicated to the development and sales of high-end motion controllers, mirror systems, servo drives, robot control systems, and customized software systems.

After years of dedicated research and development and customer use, continuous testing and improvement, the independently developed high-end motion controller and supporting control software have won full recognition and affirmation from customers with stable performance, fast speed, high precision, strong functionality, and convenient use, greatly enhancing the competitiveness of customer equipment in terms of performance price ratio. SuperFar has steadily moved towards becoming the first high-tech company in China to develop high-end multi-dimensional motion controllers.

SuperFar's series of products are widely used in industrial control fields such as laser processing equipment (marking, cutting, welding, drilling, surface modification, 3D printing, etc.), electronic industry application equipment (processing, testing), production automation equipment, CNC machine tools, printing machinery, special machine tools, robots, packaging machinery, clothing processing machinery, etc.

SuperFar continues to invest in research and development, and new series of products will be continuously introduced to the market to enhance customer competitiveness and work together with customers to create brilliance.

Certificate

Customer

Exhibition

After sale service

1. 7*24 hours online support

2. Professional after sales team support and guide

3. Powerful R&D team capable of ODM/OEM service and secondary development requirements

FAQ

Q: Can the software support secondary development?

A: We provide SDK packages to facilitate customer secondary development.

Q: What is the product warranty period?

A: Boards come with a one-year warranty, including free repair services.

Q: Can you provide on-site installation and debugging?

A: Our dedicated after-sales team assists with on-site installation and debugging.

Q: What are the main applications of this control system?

A: The QLCut sheet metal cutting control system is used for cutting Stainless steel, carbon steel, cold-rolled sheets, galvanized sheets, copper materials, aluminum substrates, and other metal laser cutting processing applications.