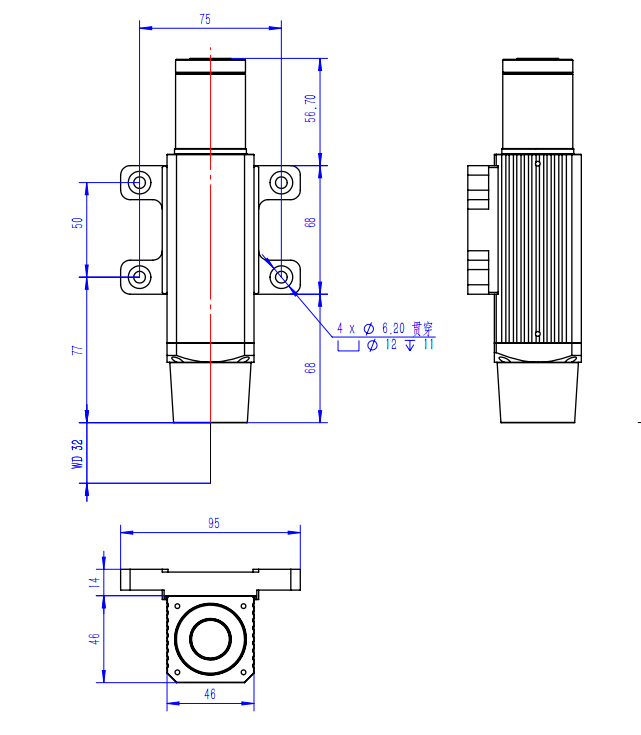

SAI-10C Bessel Cutting Head

Core Advantages:

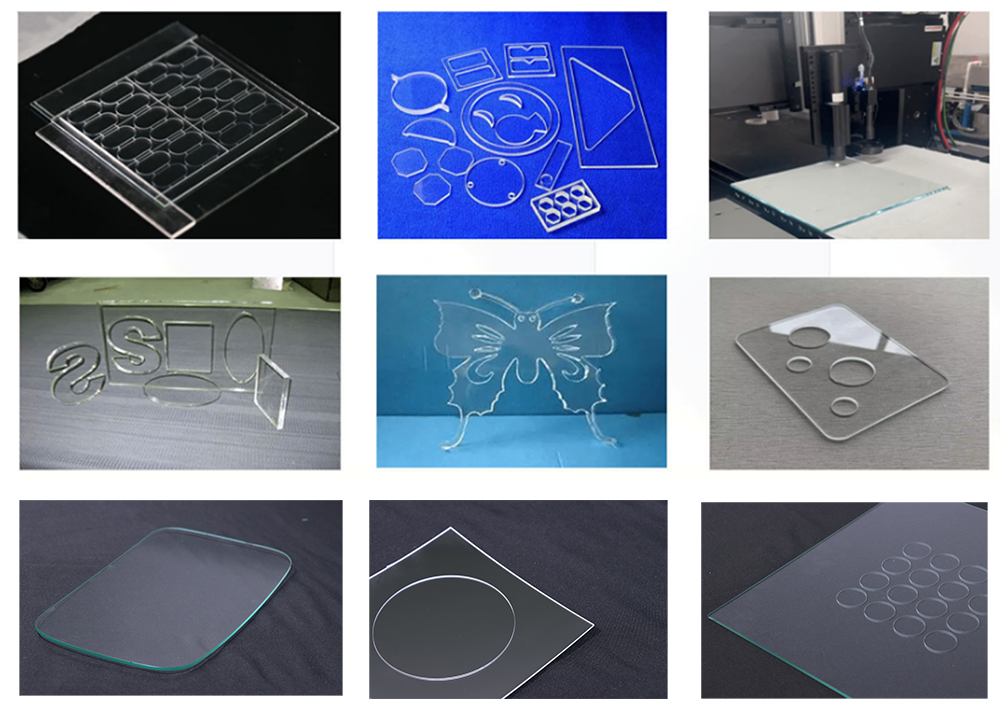

Main Application:

Glass and Cubic Zirconia cutting

Technical Parameters:

Wavelength: 1030-1070nm

Depth of Focus: 10mm (Input Spot Size: 12mm, Light Transmittance: 99%)

Maximum Input Spot Size: 12mm

Working Distance: 30mm

Applicable Lasers: Picosecond/Femtosecond lasers with PSO module and Burst mode

Installation: Fix vertically with M6 screws, ensuring it is firmly locked with the processing surface for stable cutting.

Debugging: Conduct coaxial and concentric calibration (using special tools) to ensure the accuracy of the optical path. Professional operation is recommended.

Cleaning: Wipe the upper and lower protective lenses unidirectionally with alcohol once a week to remove impurities.

Replacement: Replace the vulnerable lenses in a timely manner when they are damaged to ensure the cutting quality.