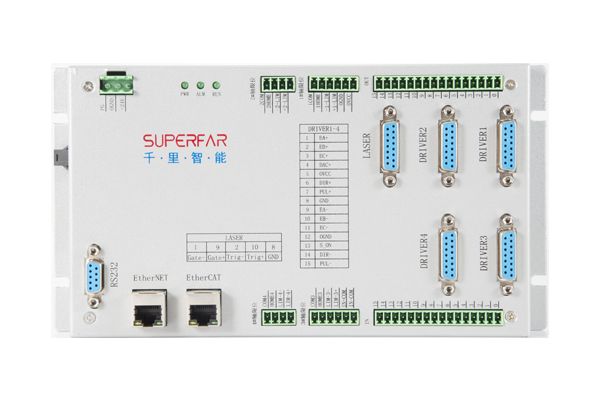

4 Axis motion control card(QLC-420)

QLC-420 4 axis motion controller, enables single or dual platform cutting and can control stepper, servo, and linear motors. Enhanced S-curve acceleration/deceleration algorithms with look-ahead control ensure faster and more stable machine operation. Designed specifically for high-precision equipment, it provides uniform corner energy control and enables fast, high-quality machining of small circles.

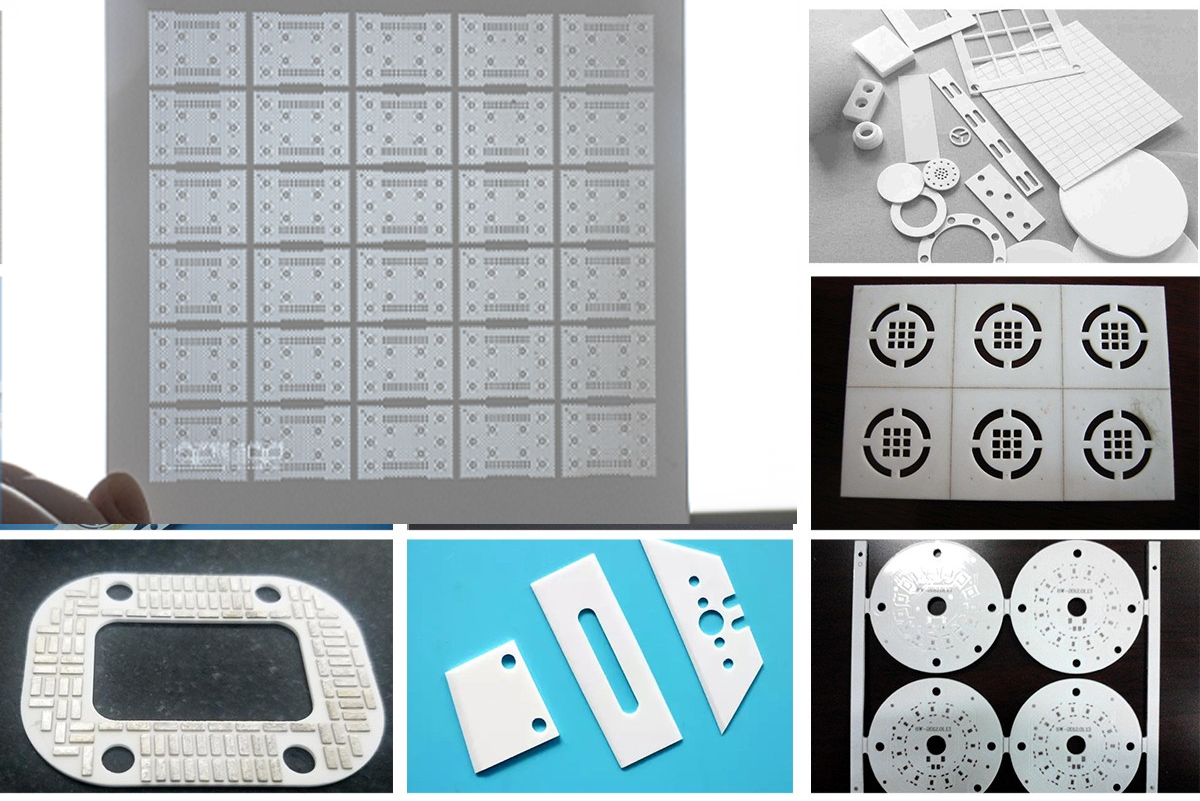

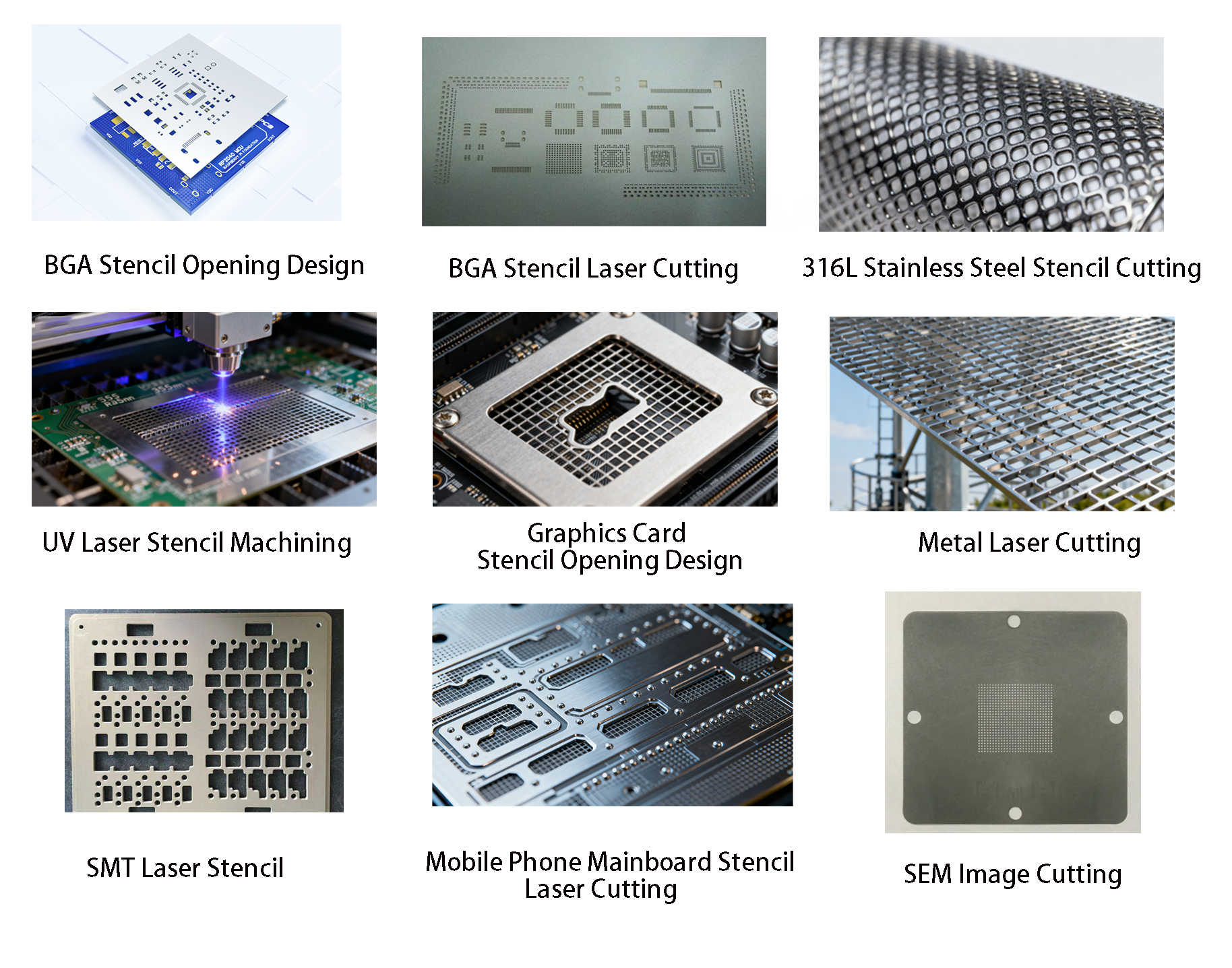

Application:

ceramic scribing, ceramic drilling, SMT metal net cutting, stencil drilling, ceramic, sapphire, glass cutting and dicing, wafer dicing, aluminum substrate cutting, large-area light guide plate marking, QR code inspection.

Category | Description |

Control Features | - Supports 4-axis analog, pulse/direction, and EtherCAT bus control -Direct drive compatibility with drives and I/O modules -Adaptable to stepper, servo, and linear motors -Enhanced S-curve acceleration/deceleration with look-ahead control for optimized machine stability -High-precision interpolation algorithm design with exceptional small-circle machining capability |

Computing Performance | - QLC-420cut platform equipped with high-performance digital processing unit. - Ultra-short servo cycle suitable for high-speed, high-precision scenarios |

Communication Capabilities | - EtherNET 1000M Ethernet communication - Independent operating system |

EtherCAT Interface | - Simplified wiring, exceptional scalability, and robust anti-interference performance |

Data Storage | - Large-capacity memory architecture supporting high-speed data throughput applications |

Extended Functions | - Gantry dual-drive synchronization, position compare and trigger functions - Pulse Synchronized Output (PSO) for laser energy control -Integrated online debugging/analysis software with compact, easy-to-install design |

Application | ceramic scribing, ceramic drilling, stencil drilling, ceramic/sapphire/glass cutting and dicing, wafer dicing, aluminum substrate cutting, large-area light guide plate marking |